Track record in the sugar industry

We have an extensive track record in supplying state-of-the-art technology to the sugar industry and the Kelvion Global Sales & Solutions PHE in Germany and Front-End Sales Spain worked together to find the best solution for the task.

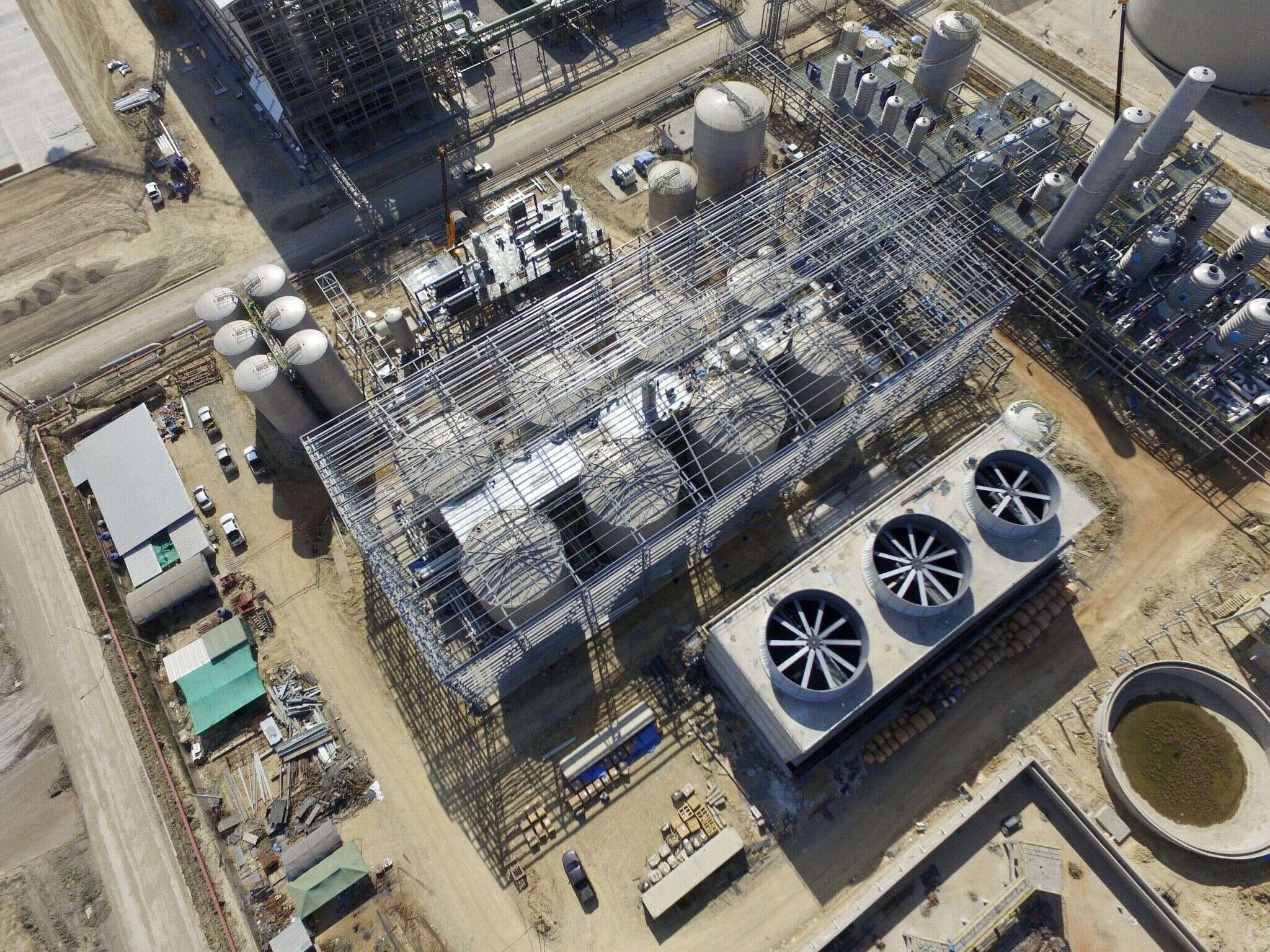

The new plant ferments sugar from molasses, which is then distilled and dehydrated. This dehydrated alcohol is used in the pharmaceutical industry and as a biofuel.

Tight delivery time

Kelvion supplied seven large evaporators for removing the water from the molasses, plus several gasketed plate heat exchangers (GPHEs) for other processes in the distillery. The customer chose GPHEs based on their compactness and cost-effectiveness.

The order worth millions was placed in March 2020 for delivery in 2 batches in June & July 2020.

The result

Excellent teamwork ensured that all equipment was delivered on time despite of the COVID pandemic lock downs.