Economiser

Energy and fuels prices increase and CO₂ emission restrictions, force us to use energy more efficient. Waste heat may be found in different process parts such as exhaust gas streams, or used drying process air. Using recovery heat exchanger and transferring heat into other process area is a basic method to increase production of the plant, or reduce fuel consumption.

Depending on process parameters, we may provide economisers with carbon steel or stainless steel materials with use of various tubes types from our portfolio. Multi stage dry / wet systems using both - carbon steel and stainless steel elements are available to give you an optimal solution with lowest possible price. Our economisers portfolio consists solutions that will heat up water, oil.

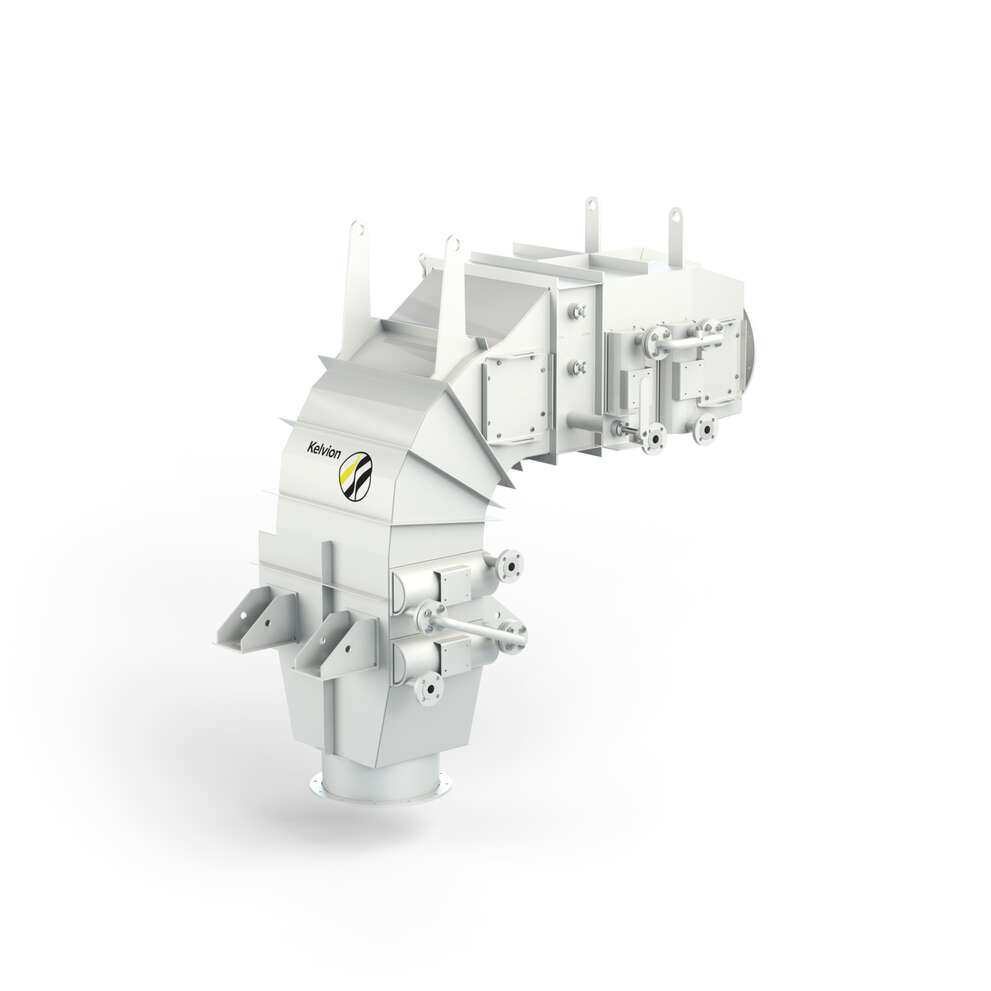

Scope of delivery may vary depending on your process needs from heat exchangers colis only to full systems containing custom made casings with safety bypass controlled by actuator.

Ecomi

An Economiser is a type of heat exchanger which is designed to use residual heat for further thermal operations. In doing so, it increases the process efficiency and lowers operating costs. As the name “Economiser” suggests, it offers customers significant economic benefits.

EcoMi takes these economic advantages even further by combining them with a modular design. This leads to even more savings, thanks to less engineering work, short lead times and shorter payback periods. Our standardised design can handle a wide range of gas flow volumes. It can also be equipped with different tube and casing types, using carbon and stainless steel, to suit your application – including condensation. With its vertical, horizontal or horizontal to vertical installation, the Economiser can be integrated in existing plants, offering you the greatest possible flexibility.