Kelvion can clean the water side of a transformer oil water cooler to remove accumulated chalk and rust deposits, which can significantly improve performance and efficiency. This will enable the transformer to operate at maximum power, through maximum or required cooling capacity, reliably and effectively for longer. The Kelvion Service includes complete overhauls, spare parts and maintenance, as well as upgrading from single to double tubes and adapting the water or oil side to meet new operational demands.

OUR SERVICE PORTFOLIO

EARLY LIFE

- Assistance to assembly and disassembly, shipping and transport

- Supervision of installation by Kelvion experts

SPARE PARTS & SPARE PART SOLUTIONS

- Gasket kits, chambers, new tube bundles, tools

- Initial spare parts

- Spare part packages

- Delivery and assembly of spare parts

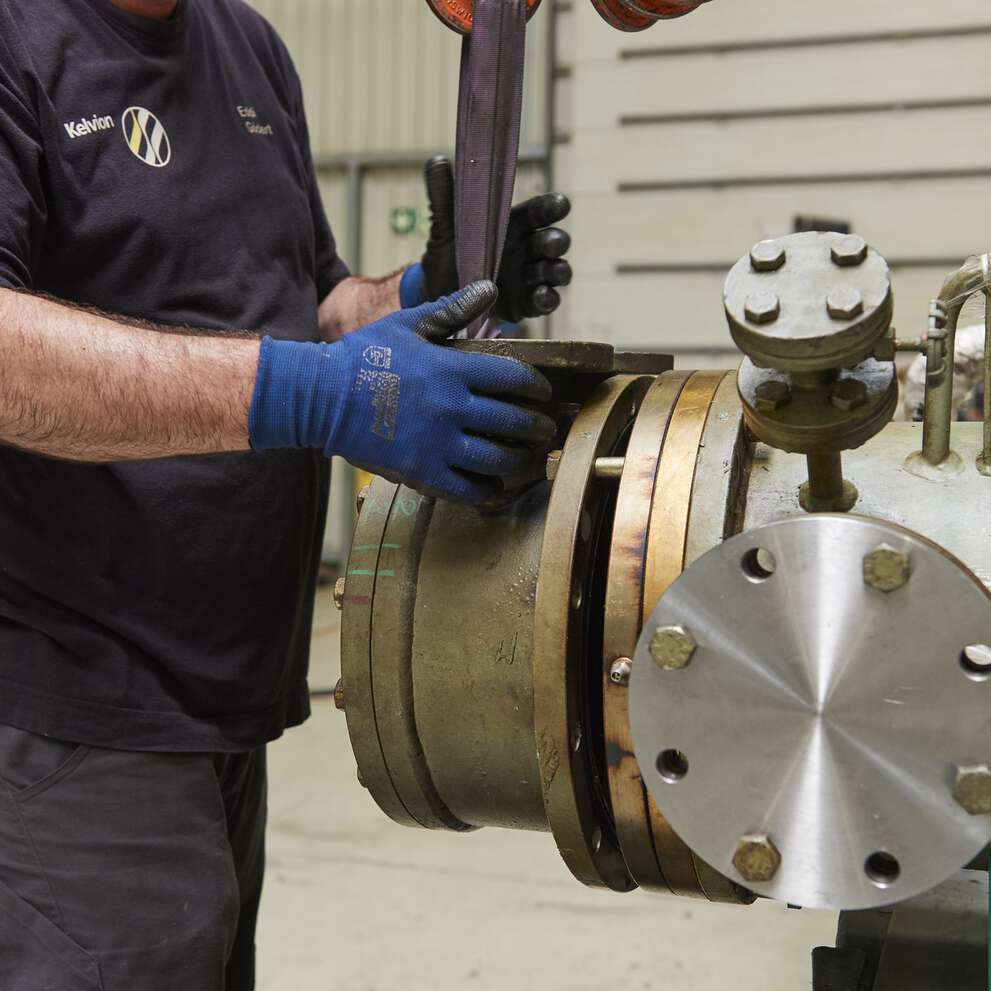

REPAIRS, OVERHAULS & MAINTENANCE

- Complete overhaul or repair

- Professional repair in workshop

- Renewal of the internal and external coating/re-coating

- Assistance to assembly and disassembly, shipping and transport

- Cleaning of inner and outer side

- Extensive damage assessment and elimination

- Flow measurement on site

- Adaptation of water and oil side to new operational demands

- Renewal of corrosion protection and exterior painting

UPGRADES & REPLACEMENTS

- Adaptation of water and oil side to new operational demands

- Complete cooler as a replacement of Kelvion and non-Kelvion products

- Replacement of bundles

- Upgrade from single tube to double tube systems

MONITORING, CONSULTING & TRAINING

- Training on cleaning of the water side

- Pressure, temperature and volume flow systems can be added at the cooler-

- Water and oil measurements

- Consulting for design, construction and optimisation of the complete plant at any stage of the project

- Function test of monitoring devices (e.g. leakage detector, oil/water flow monitors, differential pressure switch, etc.)

PROFESSIONAL CLEANING FOR MAXIMUM COOLING PERFORMANCE

The transformer oil water cooler is built for demanding tasks, yet over time it can become heavily soiled with particles of chalk and rust. Unless these are removed, the transformer loses maximum cooling capacity, which means that the unit transfers less electrical energy. Cleaning can be achieved on the water side by flushing. We can carry out a complete overhaul and tightness test and adapt the water or oil side to meet new operational demands. Upgrades include switching from a single to a double tube system and from analog to digital monitoring. The Kelvion Service engineers will also carry out on-site performance measurement.