OUR SERVICE PORTFOLIO

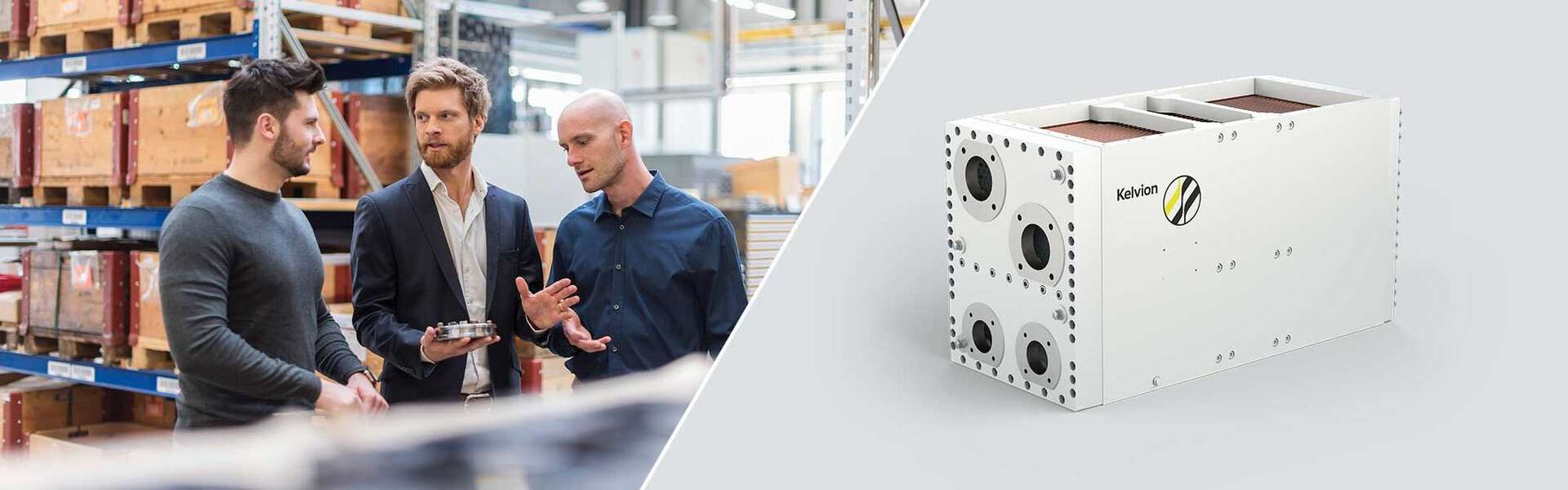

- Assistance to assembly and disassembly, shipping and transport

- Supervision of installation by Kelvion experts

- Spare parts

- Cleaning brushes

- Service kits

- Complete overhaul, repair or new production

- Renewal of corrosion protection and exterior painting

- Internal cleaning of the tube and shell side

- Cleaning (high pressure, chemical) of Kelvion and non-Kelvion products

- Brush cleaning tube side including documentation of results

- Pressure testing with 3.1 certificate

- Modifications and replacements of Kelvion and non-Kelvion products

- Examination and assessment of operating conditions

- Endoscopic examination of tube side regarding pollution, corrosion and erosion

- Examination of fin side regarding pollution, corrosion and erosion

- Analysis of water and other product samples

- Investigation of corrosion problems (destructive testing and sample analysis with specialists)

- Assessment of deposits or corrosion products which may possibly occur on the tube side

- General visual inspection and documentation of results

- Pressure test (tube and gas side) acc. to PED / DVGW (category I+II) and PED / DVGW (category III+IV, Kelvion together with 3rd party)

REPLACEMENT OF LATEST COOLING BUNDLES

Diesel and gas engines release particulates into the air which can enter open cooling water circuits and lead to an accumulation of deposits in the charge air cooler tubes. If the tubes become blocked, leakages in the joints and seals will occur. Pollutants will also corrode the fins. If the engine is started without an effective cooling water circuit, the vibrations may cause cracks in the cooler tubes and sidewalls. Kelvion recoils the coolers with new inserts, using the latest modifications, to allow optimum efficiency and reliability. Upgrades with copper-nickel alloys, stainless steel or titanium tubes and new thermal calculations are available. All repairs and modifications are subject to thorough testing. The Kelvion Service also includes replacing equipment at planned intervals, cleaning and testing and exchange programs.