OUR SERVICE PORTFOLIO

- Precise installation of equipment to make future operation and Service easier

- Supervision of installation by Kelvion experts

- Supply of highest quality spare parts

- Cleaning: Improvement of the thermodynamic performance and optimisation of the efficiency

- Repair of the equipment

- Replacement of unsafe, worn, or damaged parts

- Replacement of unsafe, worn, or damaged parts

- Troubleshooting: Detection of the root cause of a major issue by applying our extensive product and process knowledge

- Performance audit: Performance tests on the actual operating performance

- Remote support: Hotline support with direct access to experts

- Training: Staff training to increase knowledge and competencies of your maintenance staff

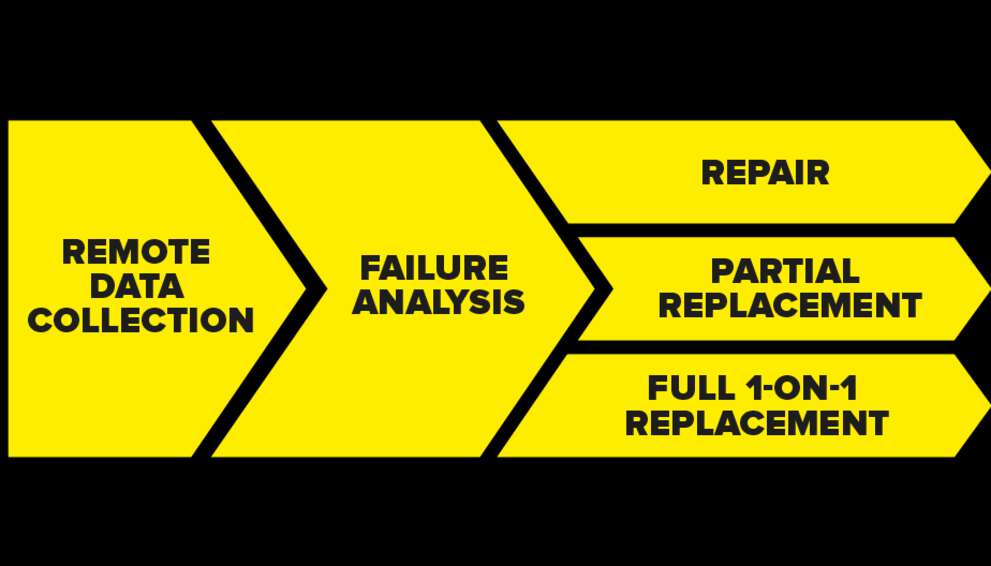

REMOTE DATA COLLECTION & FAILURE ANALYSIS

Kelvion welded plate heat exchangers, with their outstanding thermal transfer coefficients, are built for demanding applications. To avoid any risk of unscheduled downtime, it is important to inspect the condition of the equipment to offset any potential failure before it happens. We provide a range of preventative measures, including cleaning by hydro-blasting, chemical CIP and inspecting and repairing welding. Should the heat exchanger fail, we will first collect data to assess the damage then our service engineers will perform a range of tests. We always advise you not to try and open the heat exchanger – particularly a K⁰Bloc unit – without training or Kelvion supervision as this may cause further damage if done incorrectly.

Following the tests, we will advise on the best course of action to get the heat exchanger running efficiently again. This may be repair welding, replacement of parts or, in rare circumstances, full replacement of the unit. Whatever the outcome, you can be assured of a robust and reliable performance from your heat exchanger.