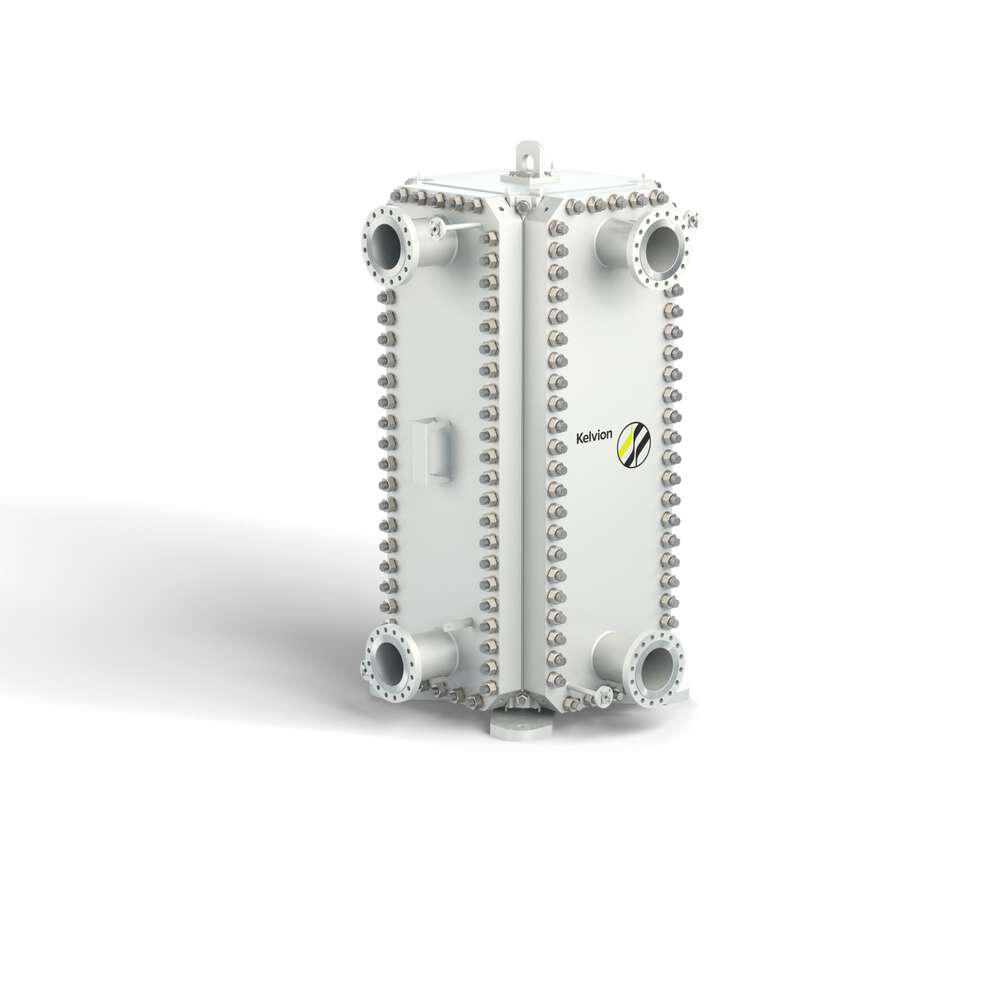

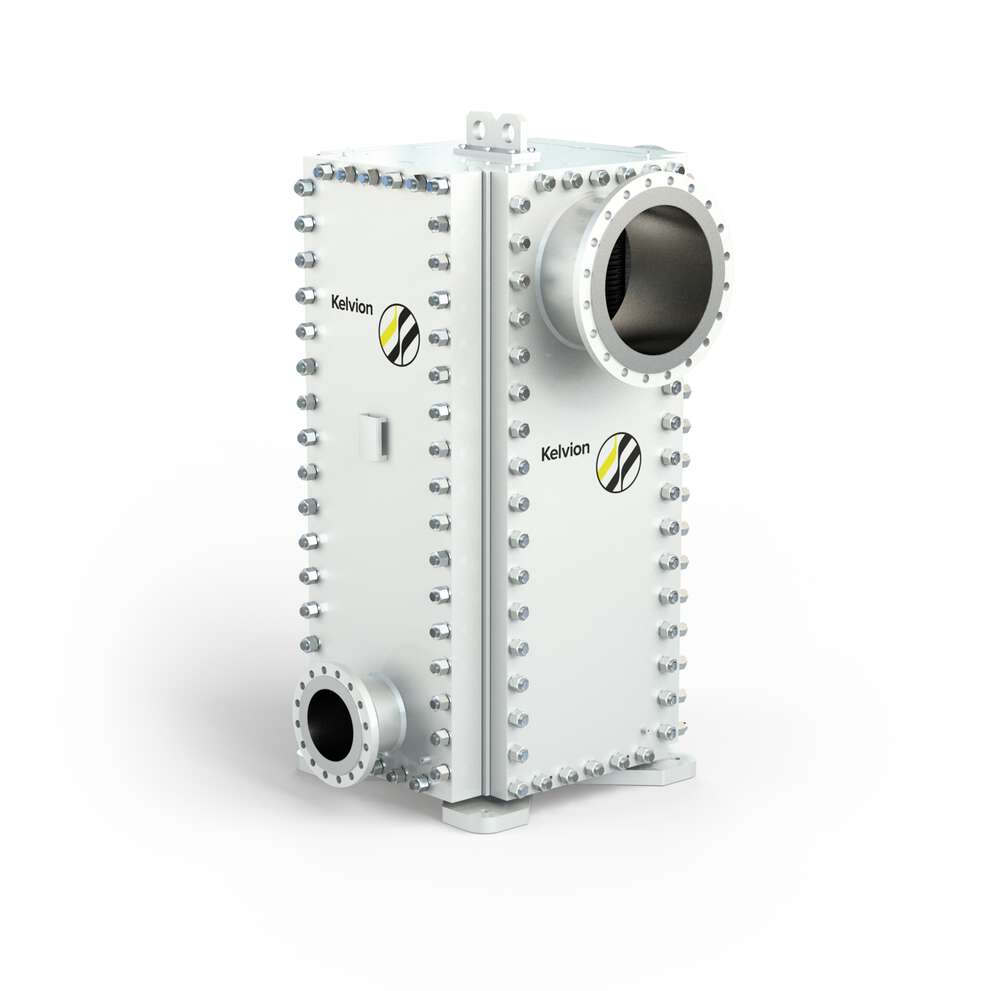

Welded Plate Heat Exchanger

K°Bloc

K°Bloc is the result of decades of experience with demanding applications, more than 30 years of plate pack welding expertise and a commitment to continuous product improvement. Now this welded plate heat exchanger has been refined to further enhance its reliability and efficiency. K°Bloc plays a leading role in Kelvion’s package of sustainable solutions, working across a broad range of liquids, temperatures and pressures.

Three different plate corrugations are available:

- Chevron corrugation offers high efficiency and pressure resistance. The high turbulence reduces fouling and is therefore the right choice for demanding applications.

- The double dimple corrugation is the first choice for highly viscous or solid containing media as well as for applications wiht low pressure drop requirements.

- The New Performance Chevron (NPC) is the latest addition for the K°Bloc family. Backed up with years of experience this new plate corrugation has been developed to meet today's requirements of high demanding applications. High heat recovery cut costs by lower energy consumption and cooling water needs. Improve sustainability by lowering the the carbon footprint.

EVERY FULLY-WELDED PLATE HEAT EXCHANGER SERIES HAS ITS OWN SPECIFIC ADVANTAGES AND AREA OF APPLICATION - THESE INCLUDE:

- High temperature and pressure resistance

- Low investment costs through heat transfer with maximum efficiency

- Small footprint

- Safe operation (gas-tight version)

- Easy to clean

Conclusion:

Developed to meet the challenges of every conceivable application, our fully-welded plate heat exchangers offer a convincing performance even under difficult circumstances and conditions. If you would like to get in touch, our expert engineers are available and happy to advise you – with one click on the button, we will send you the name and contact information of your contact person. Additionally, you can learn more details about our heat exchanger consulting and other related services.