With many years of experience in decarbonisation and hydrogen production, Kelvion's expert engineers were able to work closely with RWE Gas Storage West GmbH to modify the original specifications for the compressor station in favour of a more suitable design. Our solution involved designing and delivering three tailor-made air fin coolers optimised for pure hydrogen. While the small size of hydrogen molecules posed significant challenges, Kelvion's commitment to innovation enabled us to create a design that was not only robust but also efficient and safe. The coolers feature selected stainless-steel components with customised forged headers and bent hair pin fin tubes, allowing leakages and stress peaks to be kept to a minimum.

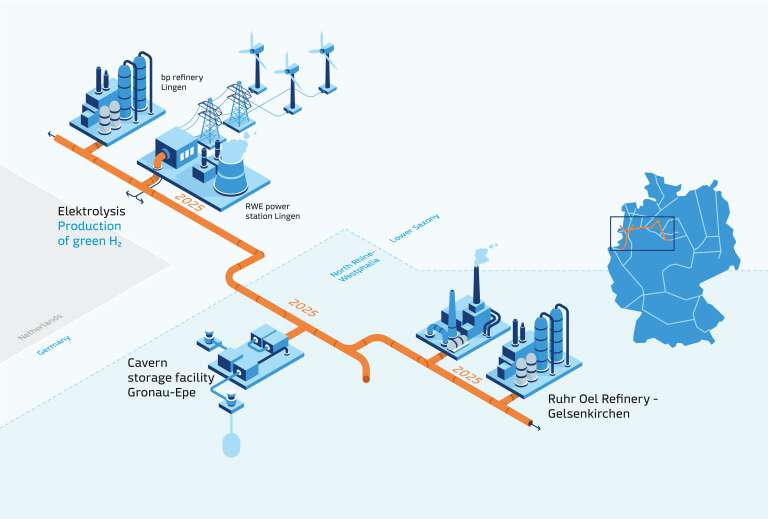

RWE Gas Storage West is contributing towards ramping up the European hydrogen economy and is therefore investing in storage facilities for green hydrogen. In this context, a new section for hydrogen is to be constructed at the natural gas cavern storage facilities of RWE at Gronau-Epe. German’s first hydrogen cavern storage facility to be used for commercial purposes is currently being built and will be operational in 2027. Storage facilities are an important part of a future European infrastructure for green hydrogen.